Vulcanized Fibre

Product List: MATERIAL OF PLASTIC FREE ERA, VULCANIZED FIBRE

List of Vulcanized Fibre products

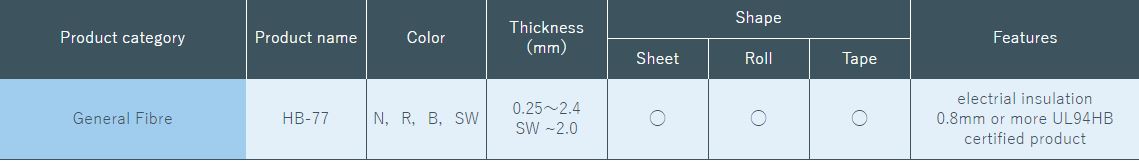

HB-77

HB-77 is the standard Vulcanized Fibre made of pulp.

It corresponds to JIS C 2315 B class.

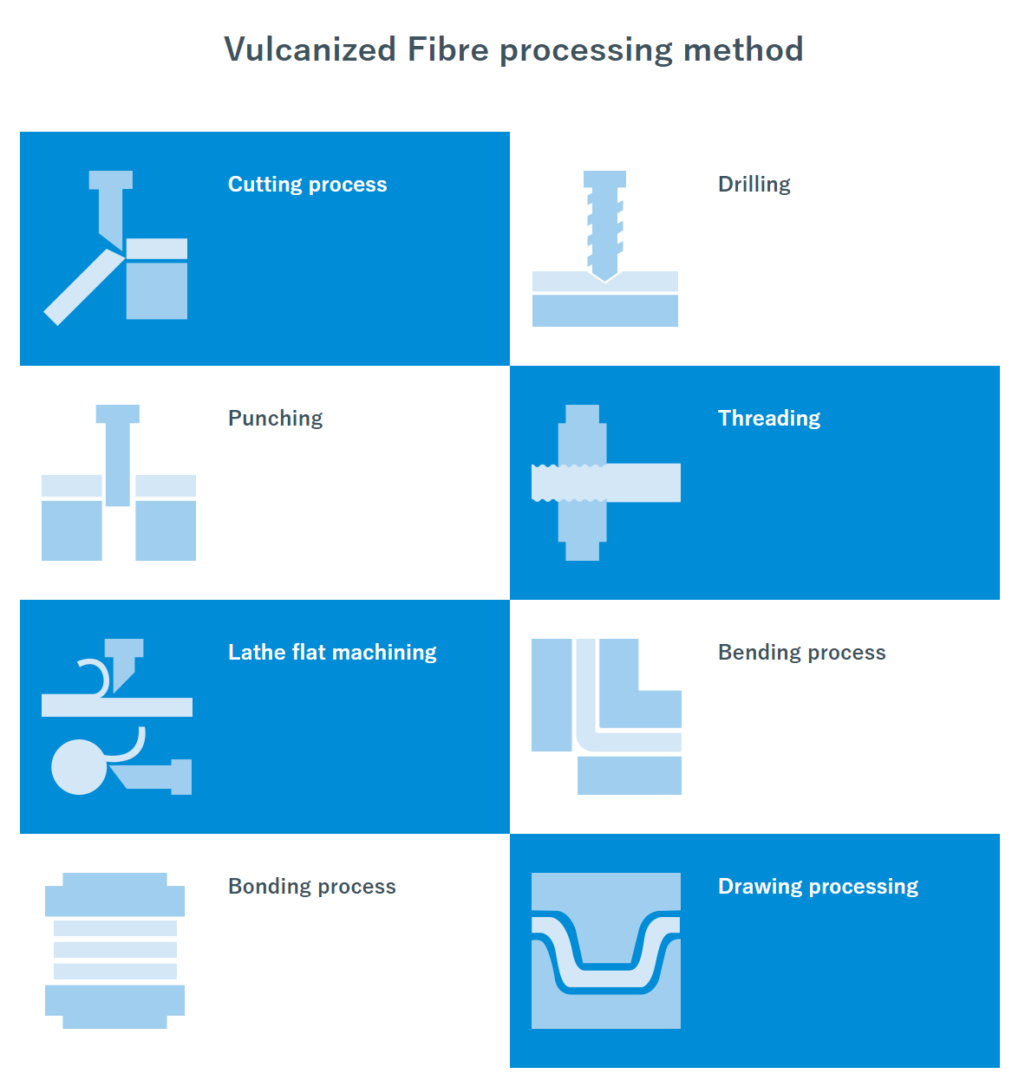

It is excellent at mechanical strength and processability (e.g. punching, bending, and drawing), and a general product used for various containers, miscellaneous goods, various packings, and machine parts as structural materials including electrical insulating materials.

Standard color: R, N, SW, B

Standard thickness: 0.25~2.4mm

Flame retardancy (UL subject 94): 0.71mm or more HB

Electrical insulation: Good

Arc resistance: 120~140Minutes

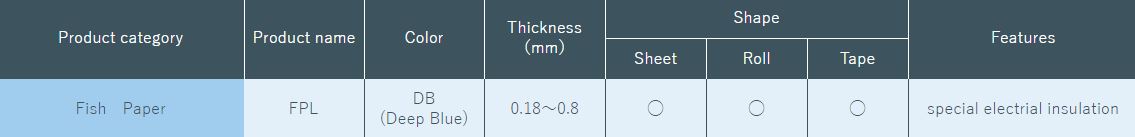

Fish Paper

FPL has excellent heat resistance and processability, and is mainly used for electrical insulation materials.

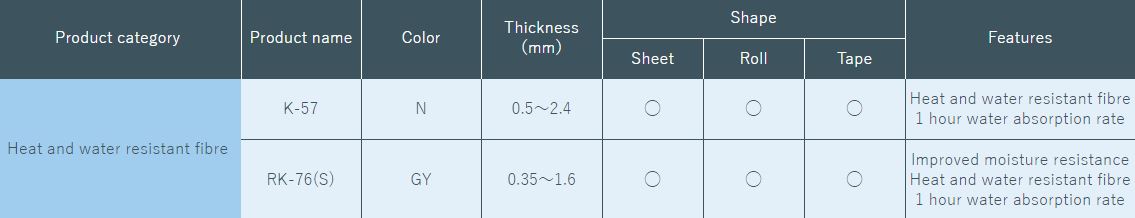

Heat and Water Resistant Fibre

K-57

K-57 is certified by the Electrical Appliance and Material Safety Law.

A product in which the properties of fibers and plastics with excellent dimensional stability are uniformly combined in the tissue.

Standard color: N

Standard thickness: 0.5~2.4mm

Water Absorption in one hour: 10%or less

Flame retardancy (UL subject94): 0.74mm or moreHB

Electrical insulation: Excellent

Arc resistance: 130~140Minutes

RK-76(S)

RK-76 (S) is a product with K-57 as a base material and urethane resin coated on the surface.

Standard color: GY

Standard thickness: 0.35~1.6mm

Water Absorption in one hour: 10%or less

Flame retardancy (UL subject94): 0.8or more HB

Electrical insulation: Excellent

Arc resistance: 130~140Minutes

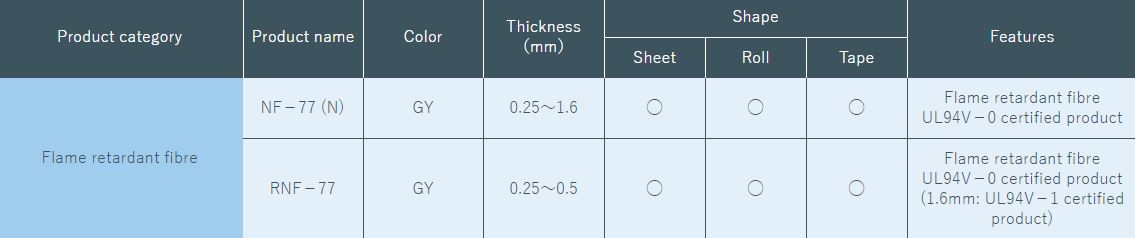

NF-77(N)

NF-77 (N) is a UL-certified product that imparts flame resistance to the base general fibre. Bending process can be performed smoothly by heating the bent part (150-200 ℃).

Standard color: GY

Standard thickness: 0.25~1.6mm

Flame retardancy (UL subject94): V-0 Certification

Hot wire: 120Minutes or more

High amp arc: 120Rounds or more

Electrical insulation: Good

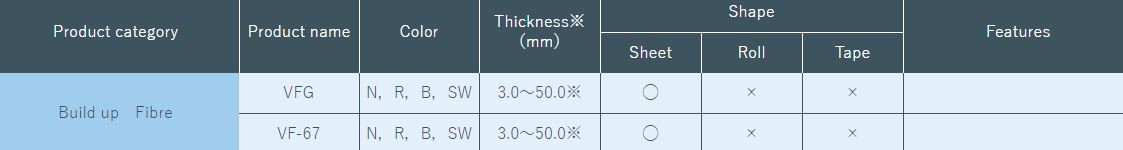

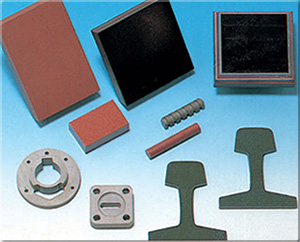

VFG・VF-67

VFG / VF-67 is a product in which a fibre single plate is used as a base material and laminated to any thickness using special resin.

As a structural material excellent in machining, it is used in various fields such as electrical insulation and sports equipment.

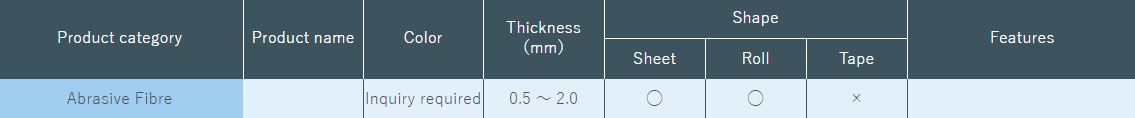

Abrasive Fibre

Abrasive fibre is a fibre used for abrasive discs. Polishing fibers require severe characteristics for use.

Our company brings together the finest selection of pulp, which is the raw material, and our unique production technology to provide products at an international level.

Thickness: 0.80mm

Density: 1.28g/㎤

Tensile strength MD: 117MPa, CD 73MPa

Internal Ply Adhesion: 3.9kg/25.4mm Width

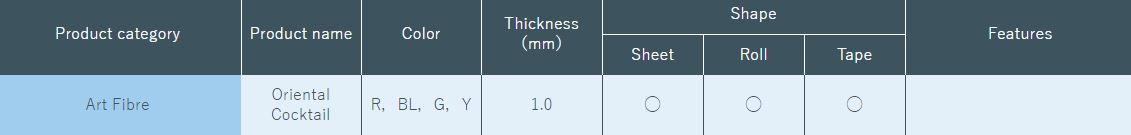

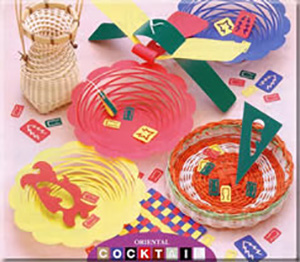

Oriental Cocktail

Oriental cocktails are characterized by vibrant colors not found in conventional products. Processing is easy, and after wetting with water, changing the shape and drying, it retains its shape and is used for stationery and art.

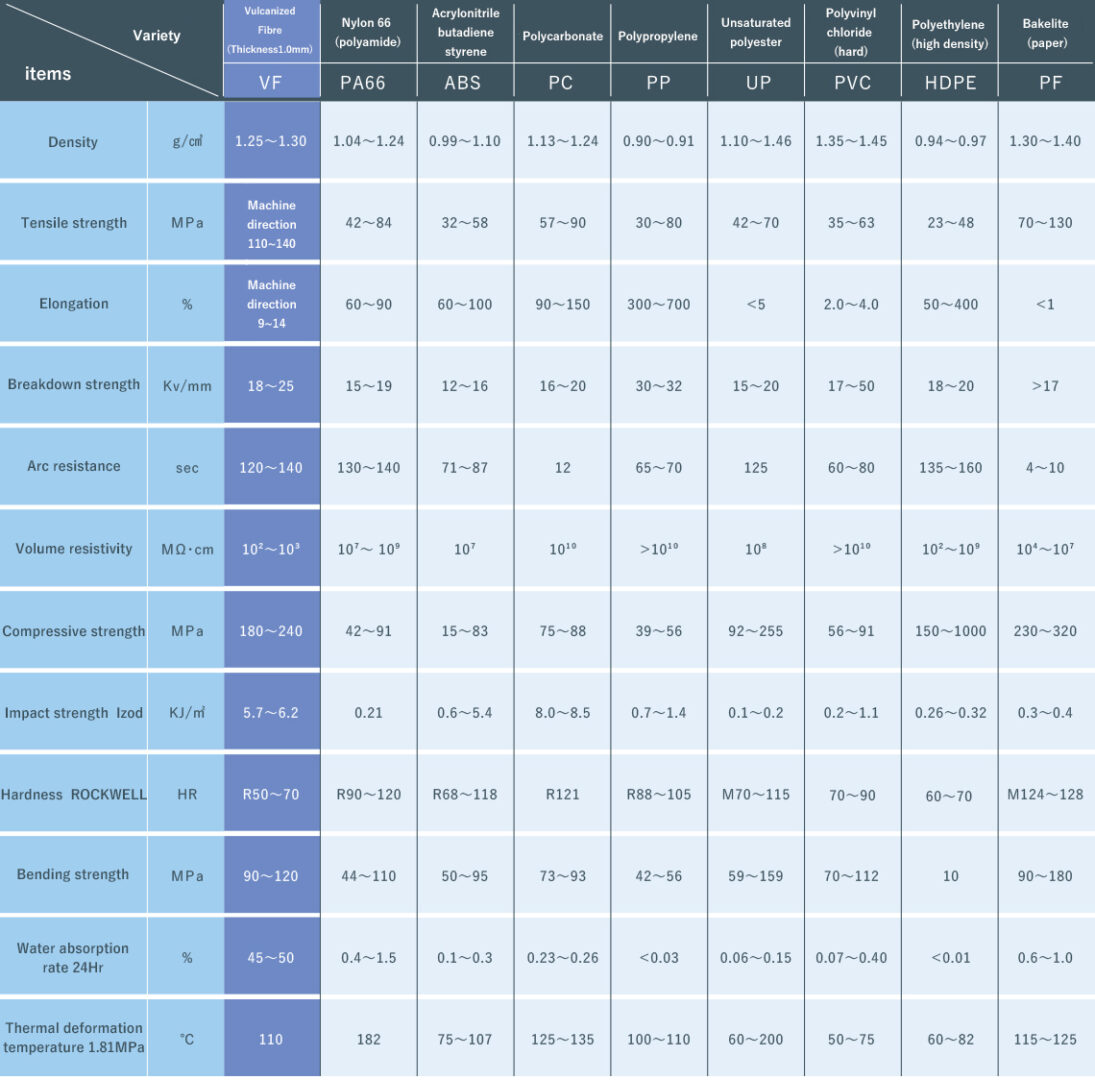

Comparison table of Characteristic values

| Test items | unit | Test conditions | General Fibre | Heat and water resistant fiber | Flame retardant fiber | ||

| HB-77N | K-57N | RK-76(S)GY | NF-77(N)GY | RNF-77GY | |||

| Thickness | mm | 23℃50%RH | 2.00 | 2.00 | – | – | – |

| Paper weight in gsm | g/m² | 2570 | 2700 | – | – | – | |

| Density | g/cm³ | 1.29 | 1.35 | – | – | – | |

| Tensile strength (Machine direction) | Mpa | 111 | 103 | – | – | – | |

| Tensile strength (Cross direction) | 60 | 55 | – | – | – | ||

| Bending resistance (Machine direction) | mm | 19.1 | – | – | – | – | |

| Bending resistance (Cross direction) | 6.4 | – | – | – | – | ||

| Thermal contraction rate (Machine direction) | % | 105℃/5hrs | 0.6 | 0.8 | – | – | – |

| Thermal contraction rate (Cross direction) | 1.4 | 1.5 | – | – | – | ||

| Thermal contraction rate (Thickness) | 3.2 | 3.0 | – | – | – | ||

| Breakdown strength | kV/mm | 23℃50%RH | – | 11.5 | – | – | – |

| 105℃/48h | 25.6 | 25.2 | – | – | – | ||

| Volume resistivity | MΩ・cm | 23℃50%RH | – | 9.0×10⁴ | – | – | – |

|

40℃90%RH/24h |

– | 1.4×10⁴ | – | – | – | ||

| Arc resistance | Minutes | 23℃50%RH | 133 | 133 | – | – | – |

| Water absorption rate | % | 23℃Water absorption1hr | – | 7.3 | – | – | – |

| Moisture | % | 105℃/48h | 10or less | 10or less | – | – | – |

| Flame retardance | UL94 | HB | HB | – | – | – | |

| Hot wire | Minutes | UL746A | 15~30 | – | – | – | – |

| High amp arc | Rounds | UL746A | 120or more | – | – | – | – |

| Test items | unit | Test conditions | General Fibre | Heat and water resistant fiber | Flame retardant fiber | ||

| HB-77N | K-57N | RK-76(S)GY | NF-77(N)GY | RNF-77GY | |||

| Thickness | mm | 23℃50%RH | 1.60 | 1.60 | – | 1.60 | – |

| Paper weight in gsm | g/m² | 2062 | 2083 | – | 2154 | – | |

| Density | g/cm³ | 1.29 | 1.30 | – | 1.35 | – | |

| Tensile strength (Machine direction) | Mpa | 114 | 105 | – | 79 | – | |

| Tensile strength (Cross direction) | 61 | 57 | – | 48 | – | ||

| Bending resistance (Machine direction) | mm | 11.8 | – | – | – | – | |

| Bending resistance (Cross direction) | 5.0 | – | – | – | – | ||

| Thermal contraction rate (Machine direction) | % | 105℃/5hrs | 0.7 | 0.7 | – | 0.6 | – |

| Thermal contraction rate (Cross direction) | 1.5 | 1.5 | – | 1.2 | – | ||

| Thermal contraction rate (Thickness) | 3.4 | 3.1 | – | 2.1 | – | ||

| Breakdown strength | kV/mm | 23℃50%RH | – | 15.6 | – | 5.3 | – |

| 105℃/48h | 28.2 | 30.6 | – | 29.0 | – | ||

| Volume resistivity | MΩ・cm | 23℃50%RH | – | 4.8×10⁵ | – | 3.4×10⁴ | – |

|

40℃90%RH/24h |

– | 2.1×10³ | – | 1.7×10² | – | ||

| Arc resistance | Minutes | 23℃50%RH | 134 | 131 | – | – | – |

| Water absorption rate | % | 23℃Water absorption1hr | – | 6.2 | – | – | – |

| Moisture | % | 105℃/48h | 10or less | 10or less | – | 10or less | – |

| Flame retardance | UL94 | HB | HB | – | V-0 | – | |

| Hot wire | Minutes | UL746A | 15~30 | – | – | 120or more | – |

| High amp arc | Rounds | UL746A | 120or more | – | – | 120or more | – |

| Test items | unit | Test conditions | General Fibre | Heat and water resistant fiber | Flame retardant fiber | ||

| HB-77N | K-57N | RK-76(S)GY | NF-77(N)GY | RNF-77GY | |||

| Thickness | mm | 23℃50%RH | 1.20 | 1.20 | – | 1.20 | – |

| Paper weight in gsm | g/m² | 1542 | 1524 | – | 1598 | – | |

| Density | g/cm³ | 1.29 | 1.28 | – | 1.36 | – | |

| Tensile strength (Machine direction) | Mpa | 121 | 104 | – | 84 | – | |

| Tensile strength (Cross direction) | 65 | 57 | – | 54 | – | ||

| Bending resistance (Machine direction) | mm | 7.9 | 16.1 | – | 34.6 | – | |

| Bending resistance (Cross direction) | 3.6 | 11.1 | – | 31.1 | – | ||

| Thermal contraction rate (Machine direction) | % | 105℃/5hrs | 0.7 | 0.8 | – | 0.6 | – |

| Thermal contraction rate (Cross direction) | 1.6 | 1.7 | – | 0.9 | – | ||

| Thermal contraction rate (Thickness) | 3.6 | 3.3 | – | 1.8 | – | ||

| Breakdown strength | kV/mm | 23℃50%RH | – | 17.4 | – | 9.2 | – |

| 105℃/24h | 30.2 | 32.1 | – | 31.6 | – | ||

| Volume resistivity | MΩ・cm | 23℃50%RH | – | 1.0×10⁶ | – | 4.9×10⁴ | – |

|

40℃90%RH/24h |

– | 6.5×10³ | – | 4.5×10² | – | ||

| Arc resistance | Minutes | 23℃50%RH | 134 | 130 | – | – | – |

| Water absorption rate | % | 23℃Water absorption1hr | – | 6.7 | – | – | – |

| Moisture | % | 105℃/24h | 10or less | 10or less | – | 10or less | – |

| Flame retardance | UL94 | HB | HB | – | V-0 | – | |

| Hot wire | Minutes | UL746A | 7~15 | – | – | 120or more | – |

| High amp arc | Rounds | UL746A | 120or less | – | – | 120or less | – |

| Test items | unit | Test conditions | General Fibre | Heat and water resistant fiber | Flame retardant fiber | ||

| HB-77N | K-57N | RK-76(S)GY | NF-77(N)GY | RNF-77GY | |||

| Thickness | mm | 23℃50%RH | 1.00 | 1.00 | 1.00 | 1.00 | – |

| Paper weight in gsm | g/m² | 1269 | 1275 | 1285 | 1285 | – | |

| Density | g/cm³ | 1.27 | 1.28 | 1.29 | 1.29 | – | |

| Tensile strength (Machine direction) | Mpa | 120 | 102 | 121 | 82 | – | |

| Tensile strength (Cross direction) | 64 | 56 | 65 | 46 | – | ||

| Bending resistance (Machine direction) | mm | 6.3 | 14.5 | – | 14.2 | – | |

| Bending resistance (Cross direction) | 2.7 | 10.4 | – | 10.8 | – | ||

| Thermal contraction rate (Machine direction) | % | 105℃/5hrs | 0.7 | 0.8 | 0.7 | 0.8 | – |

| Thermal contraction rate (Cross direction) | 1.7 | 1.8 | 1.6 | 1.5 | – | ||

| Thermal contraction rate (Thickness) | 3.7 | 3.5 | 3.1 | 2.6 | – | ||

| Breakdown strength | kV/mm | 23℃50%RH | – | 18.5 | 24.5 | 9.1 | – |

| 105℃/24h | 32.7 | 33.7 | 33.4 | 34.9 | – | ||

| Volume resistivity | MΩ・cm | 23℃50%RH | – | 1.8×10⁶ | 4.0×10⁶ | 3.2×10⁴ | – |

|

40℃90%RH/24h |

– | 6.1×10³ | 3.8×10⁴ | 2.6×10² | – | ||

| Arc resistance | Minutes | 23℃50%RH | 135 | 130 | – | – | – |

| Water absorption rate | % | 23℃Water absorption1hr | – | 6.9 | 2.5 | – | – |

| Moisture | % | 105℃/24h | 10or less | 10or less | 10or less | 10or less | – |

| Flame retardance | UL94 | HB | HB | HB | V-0 | – | |

| Hot wire | Minutes | UL746A | 7~15 | – | – | 120or more | – |

| High amp arc | Rounds | UL746A | 120or more | – | – | 120or more | – |

| Test items | unit | Test conditions | General Fibre | Heat and water resistant fiber | Flame retardant fiber | ||

| HB-77N | K-57N | RK-76(S)GY | NF-77(N)GY | RNF-77GY | |||

| Thickness | mm | 23℃50%RH | 0.80 | 0.80 | 0.80 | 0.80 | 0.80 |

| Paper weight in gsm | g/m² | 989 | 995 | 1005 | 1017 | 1052 | |

| Density | g/cm³ | 1.24 | 1.24 | 1.26 | 1.27 | 1.31 | |

| Tensile strength (Machine direction) | Mpa | 119 | 101 | 105 | 91 | 90 | |

| Tensile strength (Cross direction) | 63 | 57 | 60 | 47 | 49 | ||

| Bending resistance (Machine direction) | mm | 4.8 | 16.6 | – | 8.6 | 8.9 | |

| Bending resistance (Cross direction) | 1.8 | 13.1 | – | 4.1 | 8.2 | ||

| Thermal contraction rate (Machine direction) | % | 105℃/5hrs | 0.7 | 0.8 | 0.7 | 0.7 | 0.6 |

| Thermal contraction rate (Cross direction) | 1.8 | 1.8 | 1.6 | 1.5 | 1.5 | ||

| Thermal contraction rate (Thickness) | 3.8 | 3.5 | 2.8 | 2.5 | 2.6 | ||

| Breakdown strength | kV/mm | 23℃50%RH | – | 18.5 | 20.3 | 11.0 | 13 |

| 105℃/24h | 33.6 | 35.5 | 38.4 | 36.2 | 39.8 | ||

| Volume resistivity | MΩ・cm | 23℃50%RH | – | 5.0×10⁶ | 1.6×10⁷ | 4.1×10⁴ | 2.0×10⁵ |

|

40℃90%RH/24h |

– | 7.3×10³ | 8.3×10⁴ | 3.1×10² | 4.8×10³ | ||

| Arc resistance | Minutes | 23℃50%RH | 134 | 128 | – | – | – |

| Water absorption rate | % | 23℃Water absorption 1hr | – | 7.2 | 1.6 | – | – |

| Moisture | % | 105℃/24h | 10or less | 10or less | 10or less | 10or less | 10or less |

| Flame retardance | UL94 | HB | HB | HB | V-0 | V-0 | |

| Hot wire | Minutes | UL746A | 7~15 | – | – | 120or more | 30~60 |

| High amp arc | Rounds | UL746A | 120or more | – | – | 120or more | 120or more |

| Test items | unit | Test conditions | General Fibre | Heat and water resistant fiber | Flame retardant fiber | ||

| HB-77N | K-57N | RK-76(S)GY | NF-77(N)GY | RNF-77GY | |||

| Thickness | mm | 23℃50%RH | 0.50 | 0.50 | 0.50 | 0.50 | 0.50 |

| Paper weight in gsm | g/m² | 606 | 609 | 620 | 624 | 646 | |

| Density | g/cm3 | 1.21 | 1.22 | 1.24 | 1.25 | 1.29 | |

| Tensile strength (Machine direction) | Mpa | 114 | 103 | 114 | 90 | 98 | |

| Tensile strength (Cross direction) | 60 | 58 | 58 | 47 | 55 | ||

| Bending resistance (Machine direction) | mm | 2.2 | 14.1 | – | 5.0 | 8.5 | |

| Bending resistance (Cross direction) | 0.7 | 11.1 | – | 2.3 | 4.2 | ||

| Thermal contraction rate (Machine direction) | % | 105℃/5hrs | 0.8 | 0.8 | 0.7 | 0.6 | 0.5 |

| Thermal contraction rate (Cross direction) | 1.9 | 1.7 | 1.6 | 1.5 | 1.2 | ||

| Thermal contraction rate (Thickness) | 3.8 | 3.7 | 3.6 | 2.7 | 2.8 | ||

| Breakdown strength | kV/mm | 23℃50%RH | – | 19.0 | 29.1 | 8.3 | 17.7 |

| 105℃/24h | 37.3 | 37.2 | 36.5 | 37.9 | 37.3 | ||

| Volume resistivity | MΩ・cm | 23℃50%RH | – | 8.4×10⁶ | 8.0×10⁶ | 8.9×10⁴ | 7.3×10⁵ |

|

40℃90%RH/24h |

– | 1.4×10⁴ | 2.9×10⁴ | 4.1×10² | 3.7×10³ | ||

| Arc resistance | Minutes | 23℃50%RH | 130 | 123 | – | – | – |

| Water absorption rate | % | 23℃Water absorption1hr | – | 7.3 | 4.2 | – | – |

| Moisture | % | 105℃/24h | 10or less | 10or less | 10or less | 10or less | 10or less |

| Flame retardance | UL94 | – | – | – | V-0 | V-0 | |

| Hot wire | Minutes | UL746A | – | – | – | 120or more | – |

| High amp arc | Rounds | UL746A | – | – | – | 120or more | – |

| Test items | unit | Test conditions | General Fibre | Heat and water resistant fiber | Flame retardant fiber | ||

| HB-77N | K-57N | RK-76(S)GY | NF-77(N)GY | RNF-77GY | |||

| Thickness | mm | 23℃50%RH | 0.25 | – | – | 0.25 | 0.25 |

| Paper weight in gsm | g/m² | 254 | – | – | 287 | 308 | |

| Density | g/cm3 | 1.06 | – | – | 1.15 | 1.22 | |

| Tensile strength (Machine direction) | Mpa | 95 | – | – | 85 | 99 | |

| Tensile strength (Cross direction) | 48 | – | – | 44 | 57 | ||

| Bending resistance (Machine direction) | mm | 0.5 | – | – | 2.2 | 6.5 | |

| Bending resistance (Cross direction) | 0.1 | – | – | 0.7 | 3.5 | ||

| Thermal contraction rate (Machine direction) | % | 105℃/5hrs | 0.8 | – | – | 0.6 | 0.4 |

| Thermal contraction rate (Cross direction) | 1.9 | – | – | 1.5 | 1.0 | ||

| Thermal contraction rate (Thickness) | 3.6 | – | – | 3.2 | 3.2 | ||

| Breakdown strength | kV/mm | 23℃50%RH | – | – | – | 11.7 | 31.8 |

| 105℃/24h | 38.5 | – | – | 40.2 | 42.7 | ||

| Volume resistivity | MΩ・cm | 23℃50%RH | – | – | – | 9.9×10⁴ | 8.3×10⁶ |

|

40℃90%RH/24h |

– | – | – | 2.4×10³ | 2.8×10⁴ | ||

| Arc resistance | Minutes | 23℃50%RH | – | – | – | – | – |

| Water absorption rate | % | 23℃Water absorption 1hr | – | – | – | – | – |

| Moisture | % | 105℃/24h | 10or less | – | – | 10or less | 10or less |

| Flame retardance | UL94 | – | – | – | V-0 | V-0 | |

| Hot wire | Minutes | UL746A | – | – | – | 120or more | – |

| High amp arc | Rounds | UL746A | – | – | – | 120or more | – |

The above figures are reference values, not guaranteed values

Physical property value does not change by color, but electrical property value may become low by some color.